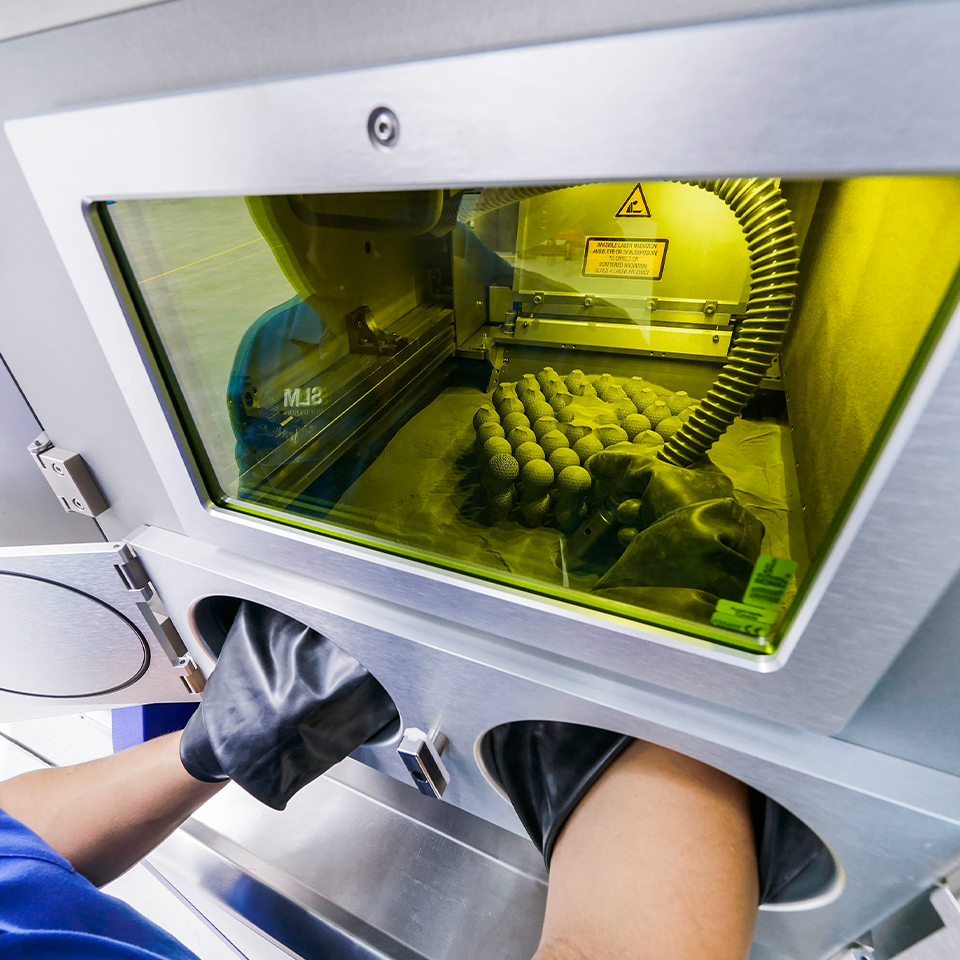

Materials

SLM® Metal Powder & Material Parameters

It only takes 3 tools to make you successful with metal additive manufacturing:

- 1. The SLM® machine fitting your needs

- 2. The metal powder that defines the later purposes and functionality of a part

- 3. Precisely engineered SLM® parameters as the missing link.

Our open parameters are the result of our vast experience in multi-laser technology and a diligent development and qualification procedure. In conjunction with the open architecture philosophy, we together with our partners have unlocked more than 45 materials to date – and counting.

Al-Based Alloys

Nikon SLM Solutions' AlSi10Mg is an aluminum-based alloy that is widely used in the additive manufacturing industry for production of functional parts as well as prototypes. AlSi10Mg is often used in applications requiring good mechanical properties and low weight.

Material characteristics

- Very good corrosion resistance

- Good electrical conductivity

- High dynamic toughness

- Excellent thermal conductivity

Typical application areas

- Aerospace

- Automotive

- Engineering

- Heat exchangers

Nikon SLM Solutions' AlSi7Mg0.6 is an aluminum-based alloy, which is often used in applications requiring excellent thermal conductivity, good corrosion resistance or tolerance to strain.

Material characteristics

- Good electrical conductivity

- Excellent SLM® processability

- Good corrosion resistance

- Good tolerance against strain

- Excellent thermal conductivity

Typical application areas

- Aerospace

- Automotive

- Heat exchangers

- Research

- Prototyping

Nikon SLM Solutions aluminium-based alloy F357 features a reduced silicon content of around

7 %, leading to increased mechanical properties, while still maintaining exceptional weldability. F357 is almost identical to the commonly known casting alloy A357, except it is completely free of the toxic element beryllium. F357 is in accordance with AlSi7Mg0.6 and already today in extended usage within aerospace or automotive applications.

Material characteristics

- Good electrical conductivity

- Excellent SLM® processability

- Good corrosion resistance

- Good tolerance against strain

- Excellent thermal conductivity

Typical application areas

- Aerospace

- Automotive

- Heat exchangers

- Research

- Prototyping

Ni-Based Alloys

Nikon SLM Solutions' HX is a nickel-based alloy with high contents of chromium, molybdenum, and iron. HX is an important alloy for high temperature applications in corrosive environments for a number of industries.

Material characteristics

- High strength

- Good ductility

- Excellent oxidation resistance at high temperatures

- High creep strength up to 850 °C

Typical application areas

- Aerospace

- Energy

- Chemical industry

- Turbine parts

Nikon SLM Solutions' IN625 is a precipitation-hardenable nickel-based material alloyed with chromium, molybdenum, and niobium. IN625 is a typical material for construction of aircraft engine components with service temperatures below 650 °C.

Material characteristics

- High strength

- Good ductility

- Excellent creep rupture strength below 700 °C

- Excellent corrosion resistance

Typical application areas

- Aerospace

- Energy

- Chemical industry

- Turbine parts

Nikon SLM Solutions' IN718 is a precipitation-hardenable nickel-chromium-alloy. With excellent tensile, fatigue, creep, and rupture strengths up to 700 °C, IN718 is an important alloy for production of components for aircraft engines, (gas) turbines, and other high temperature applications.

Material characteristics

- High strength

- Good ductility

- Excellent mechanical properties up to 700 °C

- Excellent oxidation resistance

Typical application areas

- Aerospace

- Energy

- Chemical industry

- Turbine parts

Fe-Based Alloys

Nikon SLM Solutions' stainless steel 316L is an austenitic high chromium steel with excellent processability on SLM Solutions' additive manufacturing machines. 316L is often used in applications requiring good mechanical properties and excellent corrosion resistance, especially in chloride environments.

Material characteristics

- Very good corrosion resistance

- High strength under elevated temperatures

- High ductility

Typical application areas

- Aerospace / Automotive

- Surgical instruments

- Food industry

- Offshore installations

Nikon SLM Solutions' 15-5PH is a martensitic precipitation-hardening stainless steel that has excellent processability on SLM Solutions' additive manufacturing machines. 15-5PH is suitable for applications requiring high strength and hardness combined with moderate corrosion resistance. The alloy is the ferrite-free version of 17-4PH.

Material characteristics

- Precipitation-hardenable

- Excellent tensile strength

- Moderate corrosion resistance

Typical application areas

- Aerospace

- Medical

- Chemical / Petrochemical

- Paper / Metalworking industries

Nikon SLM Solutions' 17-4PH is a martensitic precipitation-hardening stainless steel. 17-4PH is suitable for applications requiring high strength and hardness combined with moderate corrosion resistance.

Material characteristics

- Precipitation-hardenable

- Excellent tensile strength

- Moderate corrosion resistance

Typical application areas

- Aerospace

- Medical

- Chemical / Petrochemical

- Paper / Metalworking industries

Nikon SLM Solutions' 1.2709 is a maraging tool steel with a high content of alloyed nickel and some molybdenum. 1.2709 is suitable for many tooling and high performance applications that require both high strength and toughness.

Material characteristics

- Martensitic hardening

- High toughness

- High tensile strength

- Good properties up to ca. 400 °C

Typical application areas

- Injection moulding

- Engineering parts

- Automotive

- Aerospace

Nikon SLM Solutions' H13 (1.2344) is a chromium containing martensitic tool steel. This material is used in tooling applications that require exceptional strength and toughness.

Material characteristics

- High tensile strength

- Moderate corrosion resistance

- Resistant to thermal fatigue cracking

Typical application areas

- Injection moulding

- Tooling

Nikon SLM Solutions' Fe-alloy Invar 36® is a high nickel containing steel that has a uniquely low coefficient of thermal expansion below its Curie temperature of 280 °C. Invar 36® is used in components that require a high dimensional stability over a wide range of temperatures.

Material characteristics

- Low coefficient of thermal expansion below its Curie temperature of 280 °C

- Excellent mechanical properties at cryogenic temperatures

- Low tendency to fatigue at low temperatures

Typical application areas

- Aerospace

- Valves in engines

- Precision instruments

1.4828 is another austenitic stainless steel in Nikon SLM Solutions’ portfolio with very unique characteristics for steels: high strength and scale-resistant up to 1000°C. This makes it the material of choice for high-temperature, load-bearing components in furnaces, machines, and automotive applications.

Material characteristics

- Austenitic stainless steel

- High temperature resistance up to 1000°C

- High strength and scale-resistance at high temperatures.

Typical application areas

- Automotive

- Machines

- Furnaces

Ti-Based Alloys

Nikon SLM Solutions' titanium alloy Ti6Al4V ELI (Grade 23) is the high purity version of Ti6Al4V (Grade 5), the most widely used titanium-based alloy in the world. Due to its high strength, low density, and good corrosion resistance, Ti6Al4V is highly suited for production parts in the aerospace and automotive industries as well as in biomedical applications.

Material characteristics

- Good corrosion resistance

- High specific strength

- High cycle fatigue strength

- High toughness

Typical application areas

- Aerospace

- Automotive

- Medical

- Energy

TA15 is a near-alpha titanium-alloy with additives of aluminum and zirconium. The high specific strength of components made of TA15 combined with their high load-bearing capacity and temperature resistance enable them to be used for heavy-duty components in aircraft and engine construction.

Material Characteristics

- Very good mechanical properties also in the high-temperature range

- High loadability even in multiaxial stress states

- High specific strength

- Good weldability

Typical application areas

- Aerospace

- Engine construction

Nikon SLM Solutions' Ti (Grade 2) is a commercially pure titanium grade with excellent biocompatibility and good mechanical properties. Ti (Grade 2) is widely used in many different applications that require excellent corrosion resistance, strength, ductility, and low density.

Material characteristics

- Excellent biocompatibility

- Excellent corrosion resistance to sea water

- Good ductility

- Moderate strength

Typical application areas

- Medical

- Aerospace

- Energy

- Chemical / Petrochemical

- Heat exchanger

Co-Based Alloys

Nikon SLM Solutions' CoCr28Mo6 is a cobalt, chromium, and molybdenum alloy with versatile applications. Owing to its exceptional biocompatibility, CoCr28Mo6 is used in the medical industry for the production of implants and prostheses. The material is also used to produce components for application in high temperature environments such as jet-engines.

Material characteristics

- Exceptional biocompatibility

- Heat resistant

- Resistance to thermal fatigue

- Oxidation resistance

Typical application areas

- Medical

- Aerospace

- Energy

- Turbine parts

Nikon SLM Solutions' SLM MediDent® is a cobalt, chromium, molybdenum, and tungsten alloy especially designed for application in the dental industry. SLM MediDent® is used primarily for the production of biocompatible dental implants and prostheses – and has a CE certification.

Material characteristics

- Biocompatible

- Corrosion resistant

Typical application areas

- Dental

- Medical

Cu-Based Alloys

The low-alloyed copper-alloy CuNi2SiCr is a thermally hardenable alloy with a high stiffness, even at elevated temperatures. Due to the low additives, the properties of pure copper (e.g. strength, softening temperature) can be considerably improved, while other properties (e.g. electrical conductivity, thermal conductivity, corrosion resistance) are largely retained. Typical areas of application are, for example, toolmaking, conductive contacts in electrical engineering or valves.

Material characteristics

- Balanced combination of electrical and thermal conductivity

- High wear resistance

- High corrosion resistance, in particular to stress corrosion cracking

Typical application areas

- Welding technology

- Electrical engineering

- Tool construction

CuCr1Zr is Nikon SLM Solutions’ copper alloy with the lowest concentration of alloying elements and, therefore, brings an excellent balance of mechanical and conductive properties. With up to 92 % IACS after heat-treatment, CuCr1Zr still features very high electrical conductivities at up to 300 MPa ultimate tensile strength. Chromium and zirconium help to maintain both high strength and hardness at elevated temperatures – ideal for rocket engines.

Material characteristics

- Highest electrical conductivity for SLM® copper alloys

- High temperature stability for strength and hardness

- Improved strength compared to pure copper

Typical application areas

- Aeronautics and space

- Electrical engineering