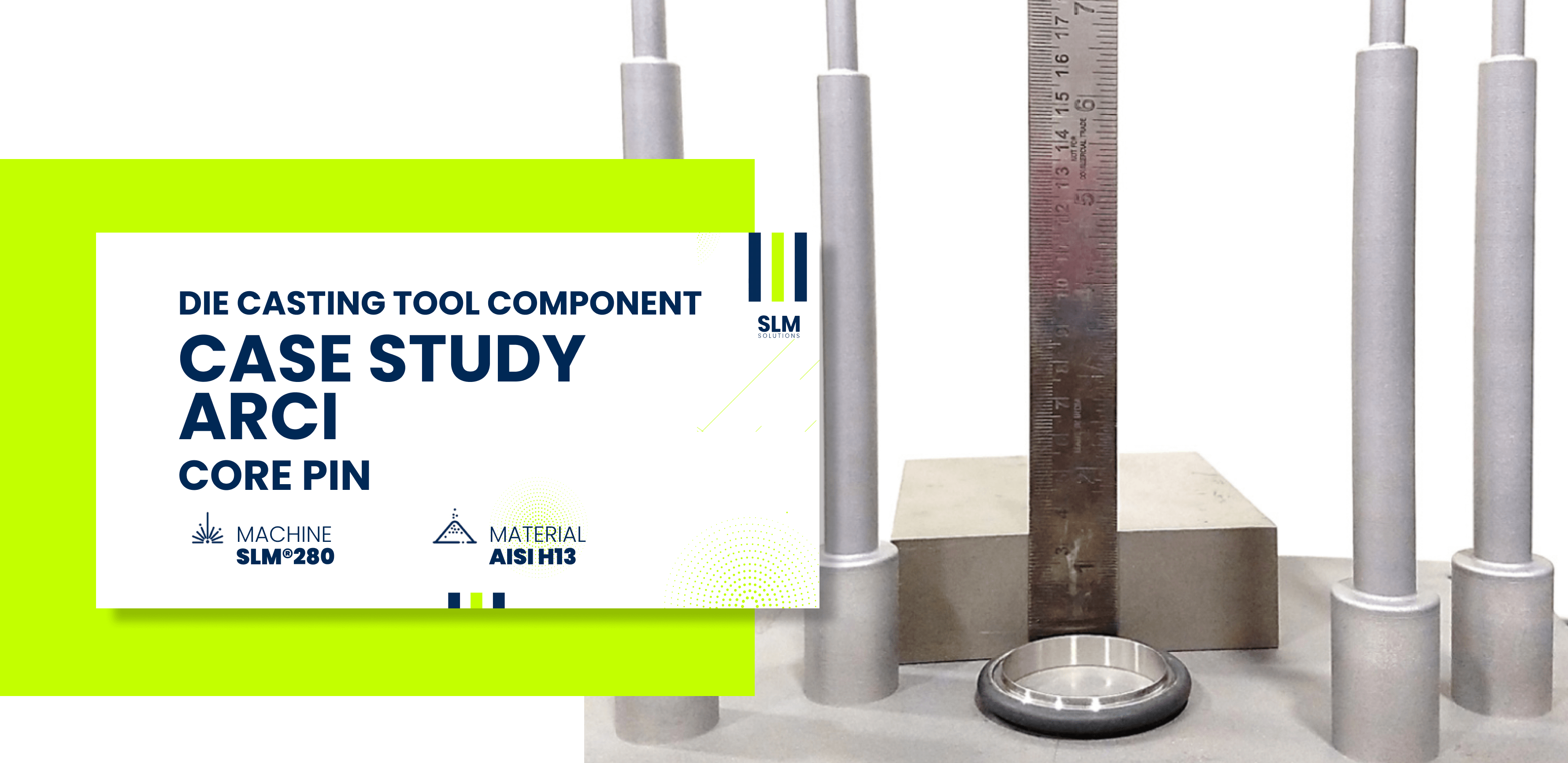

Discover how ARCI successfully manufactured a modified core pin for pressure die casting with a specially designed cooling channel.

In this case study you'll learn how the SLM® 280 provided the advantage of producing the part with precision, making it possible to design the cooling channel, resulting in improved component performance in real-time service. The project demonstrated the capability of SLM® technology to produce high-performance components for niche markets.

Want to take off with your own application? Download this case study for a comprehensive insight.

For further information, talk to our experts!

DOWNLOAD NOW

Don't miss out on the opportunity to stay ahead of the competition and unlock the full potential of your manufacturing process. Download your copy below!