Additive Manufacturing for the Automotive Industry

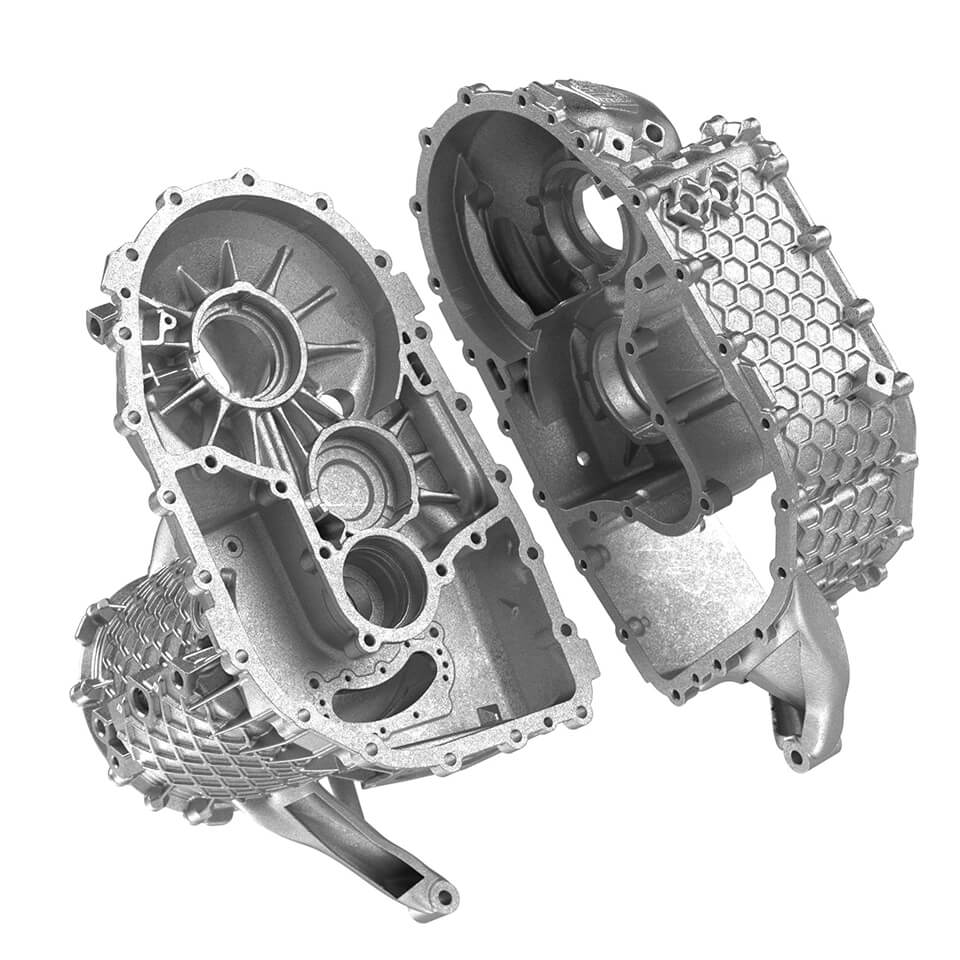

Metal 3D Printing Solutions for Automotive

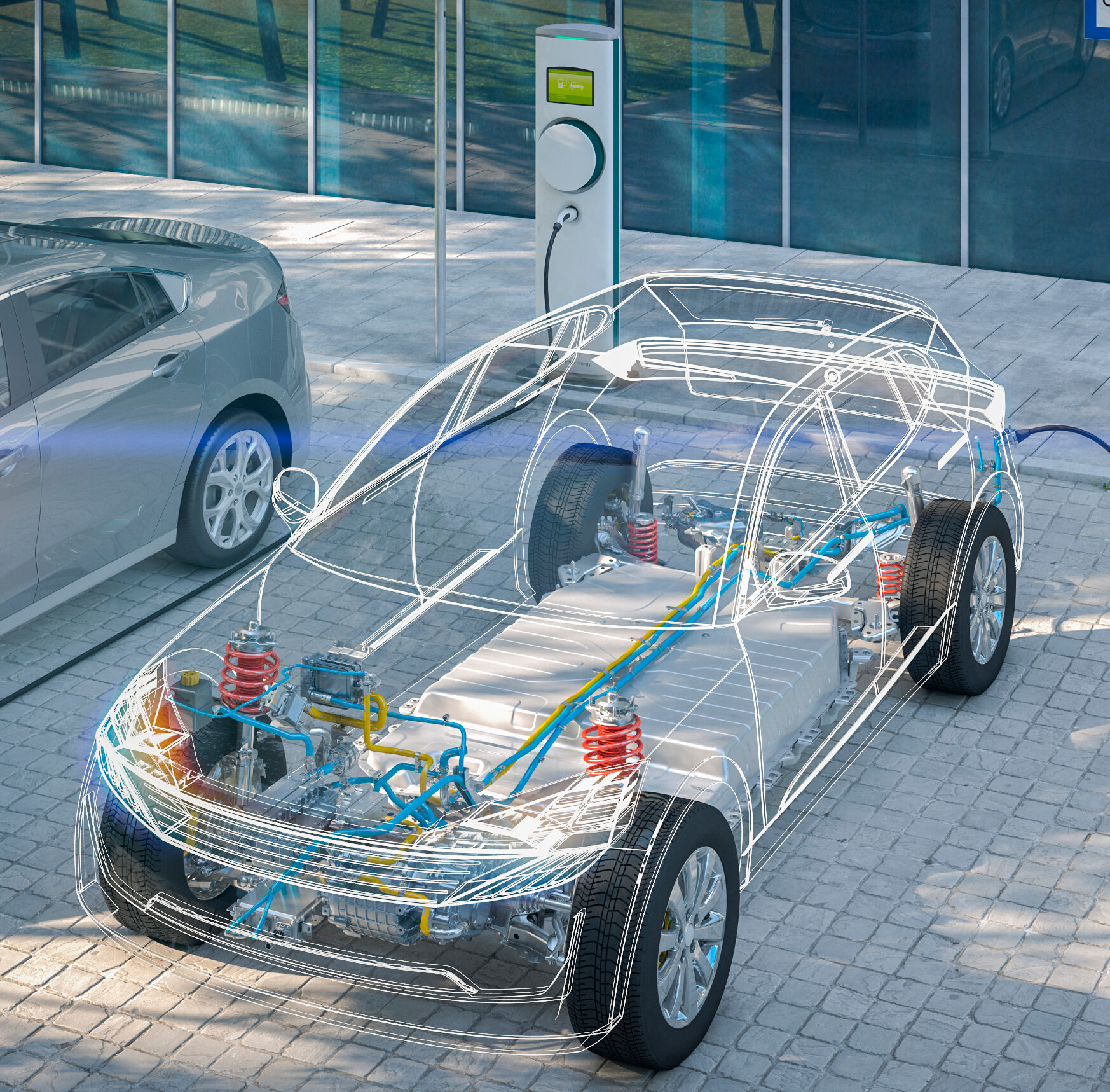

Accelerate Automotive industry product development with additive manufacturing. Leading automotive OEMs and Tier 1s build a more scalable on-demand, local-for-local supply chain of the future to get to market faster. Reduce cost while improving performance functionality with topology optimization. Tooling delayed? Bridge the gap between prototyping and serial production catering to volumes that would be costly and time consuming via Nikon SLM Solutions Technology.

Nikon SLM Solutions' expert application support helps to develop components optimized for Selective Laser Melting, from prototype to production. See below the numerous possibilities using SLM® technology for the automotive industry.

Nikon SLM Solutions is a powerful, long-term strategic partner for Divergent 3D, working with us to provide 3D metal printing hardware and software specific to the Divergent Adaptive Production System™. We believe that this will transform the way vehicle structures are designed, engineered, manufactured and assembled.

SLM® Material for Automotive Applications

Nikon SLM Solutions sells appropriate powder and parameter sets for the most common powders in the automotive industry:

- Al-Based Alloys: AlSI10Mg and ALSi7Mg

- Ni-Based Alloys: Inc. 625

- Fe-based Alloys: 1.2709, 316L (1.4404)

Selective Laser Melting Solutions for Automotive Applications

Quality Standards for Automotive Industry

Nikon SLM Solutions is here to provide machine systems that fulfill industrial safety standards, and help automotive manufacturers to certify their AM process according the automotive QS standard, like IATF 16949. Allow us to share our knowledge with you to boost your metal additive manufacturing production, contact us today!