SLM®125

Compact, accurate high power printing for low powder volume applications. The smallest machine in the SLM Solutions’ lineup, the SLM®125 is ideal for a variety of users, from rapid prototyping and low volume manufacturing to serial production and research work.

- 125 x 125 x 125 mm build envelope

- Single laser

- Multi-material

High Power Laser in a Compact Footprint

Offering a larger build plate and higher-powered laser than other similar-sized machines, the SLM®125 is a flexible manufacturing system to fit users’ specific needs. Metal additive manufacturing beginners can develop processes that scale to larger SLM® systems, research institutes benefit from a material development toolkit and production facilities can run prototype, small series and qualified production components. All selective laser melting powders, including reactive materials, can be processed on the SLM®125.

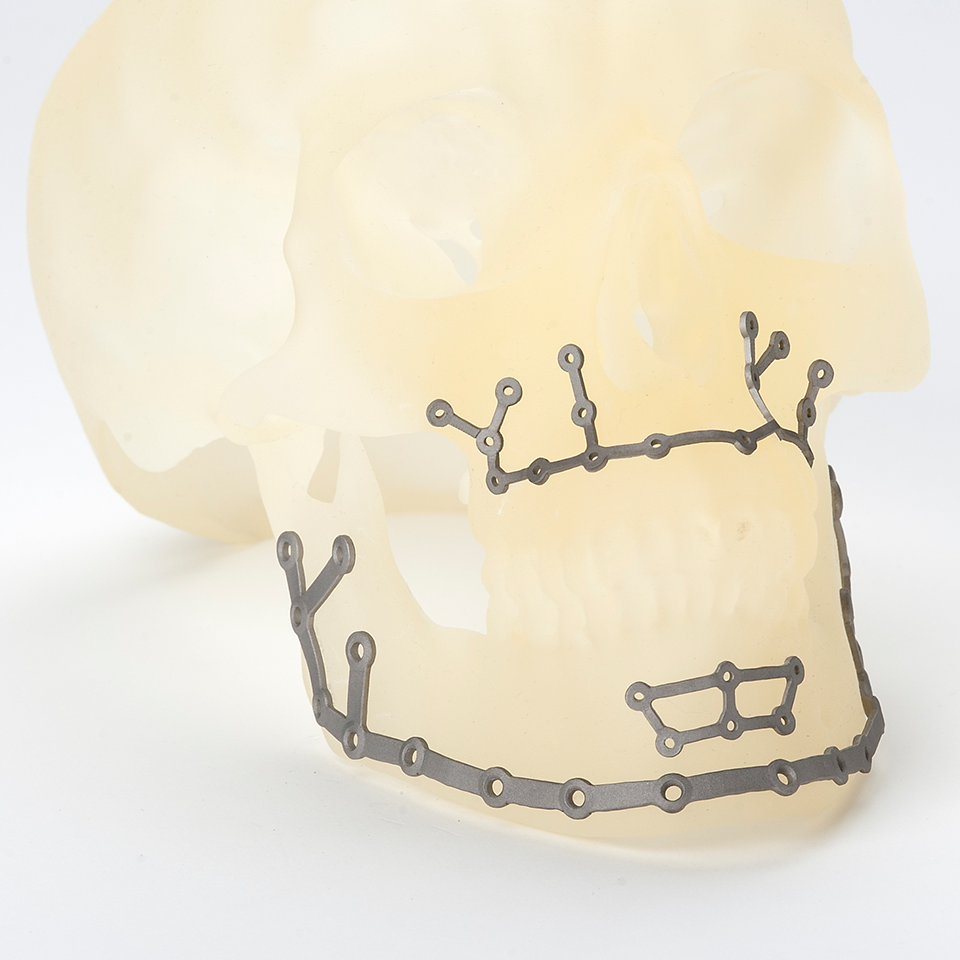

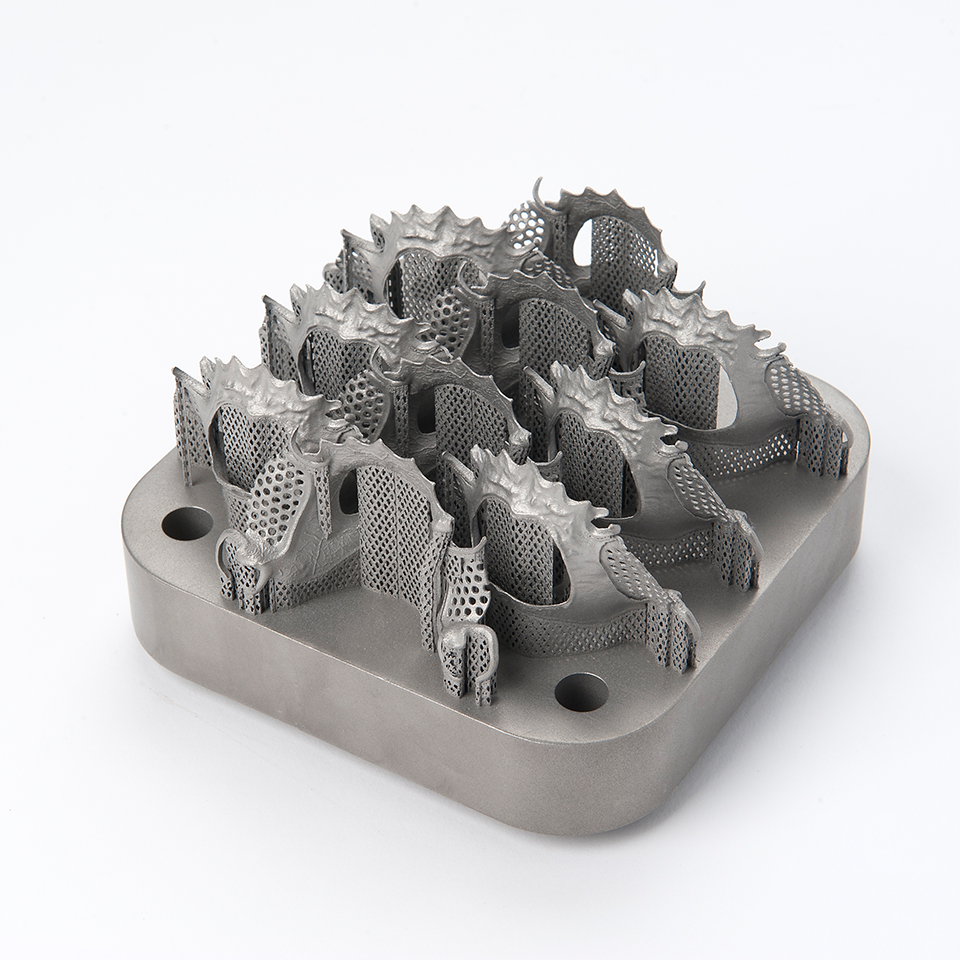

SLM®125 Real World Parts

SLM®125 Accessories

The PSM unit sieves and separates metal powder under inert gas conditions. Metal powder collected from overflow cans in the selective laser melting system is manually supplied to the sieving station. The sieved GO grain and oversized powder are collected in separate cans underneath the system for further use.

The sieving process runs automatically without influence on the running build process, reducing ancillary times. To support and speed up the sieving procedure, an ultrasonic cleaning device is added.

PSM combined with SLM®125 creates a closed-loop powder handling system, enabling the processing of both reactive and non-reactive metals.

Tool for visualizing thermal emission of the melt pool in the SLM® process. The system records the thermal radiation produced from the melt during the entire production process.

- Sequential output of thermal emission plot images of individual layers

- Detect irregularities and defects in parts

- Log and document build jobs in MPM-Files

Permanent on-axis laser power monitoring system that measures and illustrates nominal and actual power during the ongoing manufacturing process.

- Active warnings, highlighting spots with critical laser power deviation

- Documentation of the laser power for each scan vector over the entire build job

SLM®125 Technical Specifications

Build Envelope (L x W x H): | 125 x 125 x 125 mm |

Build Volume Reduction (L x W x H): | 50 x 50 x 50 mm |

3D Optics Configuration: | Single (1x 400 W) IPG fiber laser |

Build Rate: | up to 25 cm³/h |

Variable Layer Thickness: | 20 µm - 75 µm, 1 µm increments |

Minimum Feature Size: | 140 µm |

Beam Focus Diameter: | 70 µm - 100 µm |

Maximum Scan Speed: | 10 m/s |

Average Inert Gas Consumption in Process: | 0,6 l/min (argon) |

Average Inert Gas Consumption Purging: | 70 l/min (argon) |

E-Connection / Power Input: | 400 Volt 3NPE, 32 A, 50/60 Hz, 3 kW |

Compressed Air Requirement / Consumption: | ISO 8573-1:2010 [1:4:1] 7 bar |

Dimensions (L x W x H): | 1400 mm x 900 mm x 2460 mm |

Weight: | 700 kg dry |