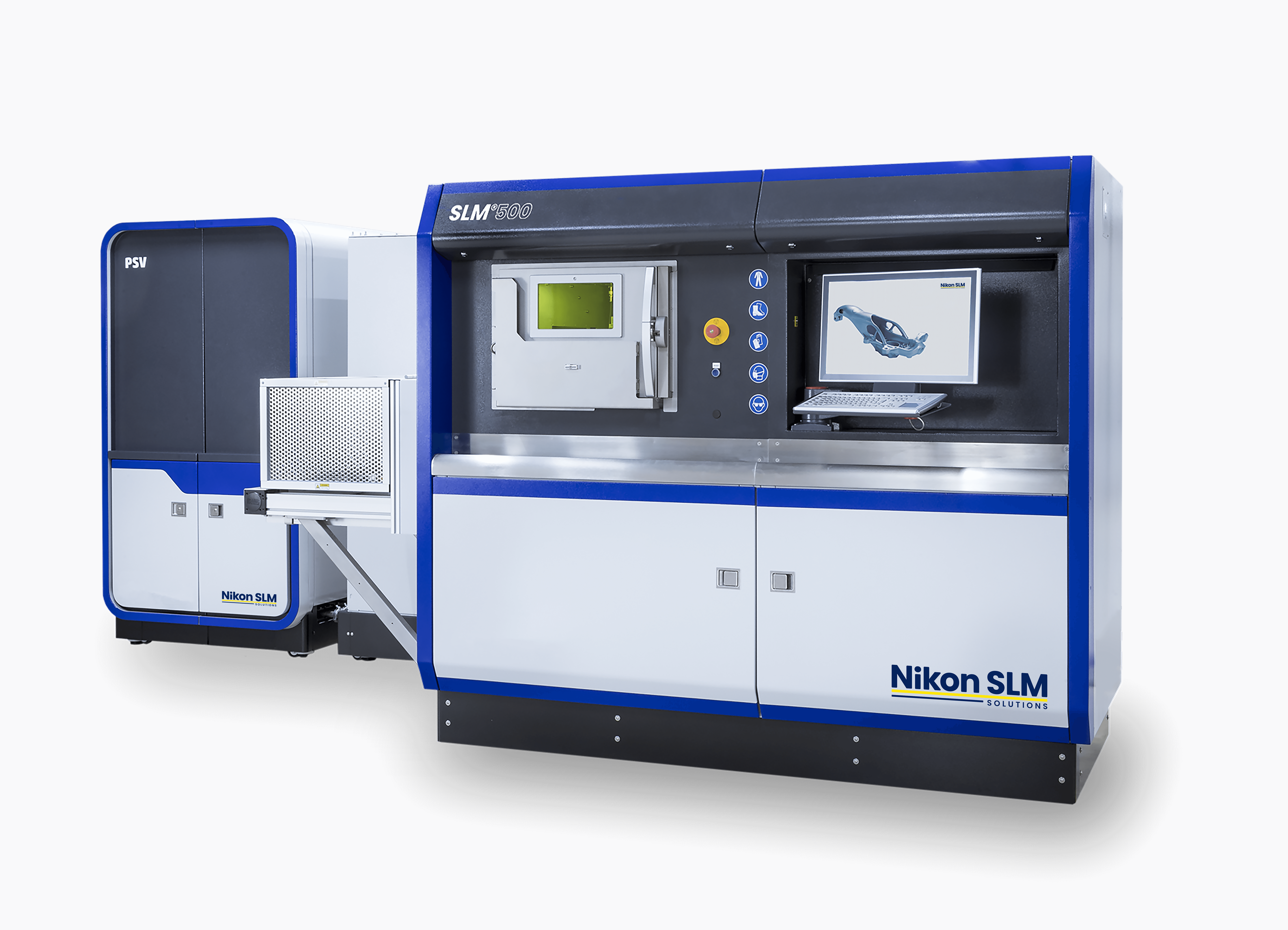

Featuring multiple lasers, closed-loop powder handling and upgraded process control ideal for demanding applications requiring high productivity.

The first quad-laser metal system on the market, SLM®500 can integrate lasers independently or in parallel to increase build rates by 90% over twin laser configurations.

Metal 3D printing with multiple lasers and closed-loop powder handling. The SLM®280 2.0 is ideal for medium to high volume metal additive manufacturing part production and prototypes.

The SLM®800 features an extended z-axis for large-scale production and the ability to connect multiple machines via the SLM HUB® opens new possibilities for serial production.

The SLM®125 is ideal for a variety of users, from rapid prototyping and low volume manufacturing to qualified series production and R&D.

Door-integrated glove boxes on all machines eliminate direct contact of powder by operators and maintains powder quality. This holistic powder-handling approach also implements a double-valve system on all powder bottles and hoppers to ensure the complete separation of operator and exposed powder.

SPEAK TO OUR EXPERTS

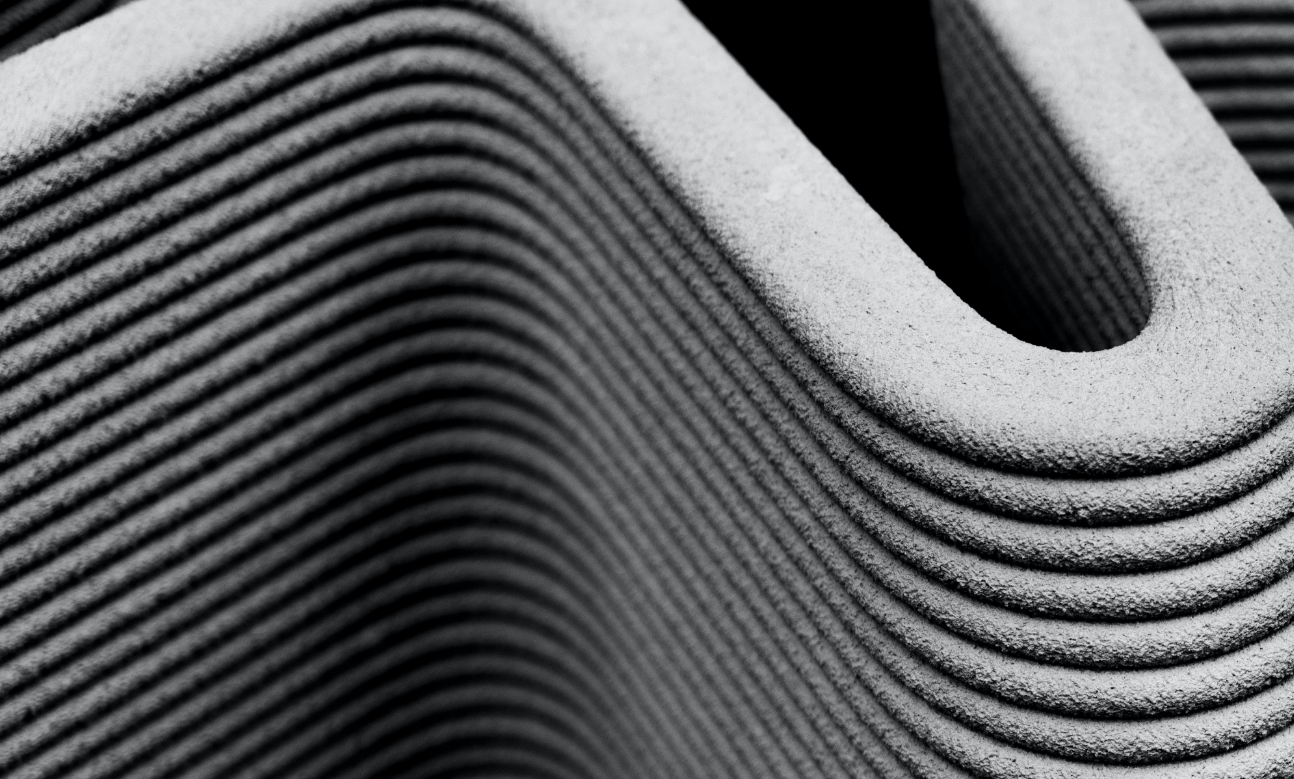

Comprehensive monitoring and quality assurance enable a high degree of process documentation and verification. SLM® machines offer:

Melt Pool Monitoring (MPM) - Visualizing the melt pool, data from MPM can be used as a resource for efficiently developing and evaluating the process parameters. In the production of safety-critical parts, the data collected serves as documentation for quality assurance.

Laser Power Monitoring (LPM) - Continuously measures and documents target and actual emitted laser output throughout the production process.

Layer Control System (LCS) - A testing and documentation system that examines the performance of each powder layer by monitoring the powder bed and detecting possible coating irregularities.

LEARN MORE

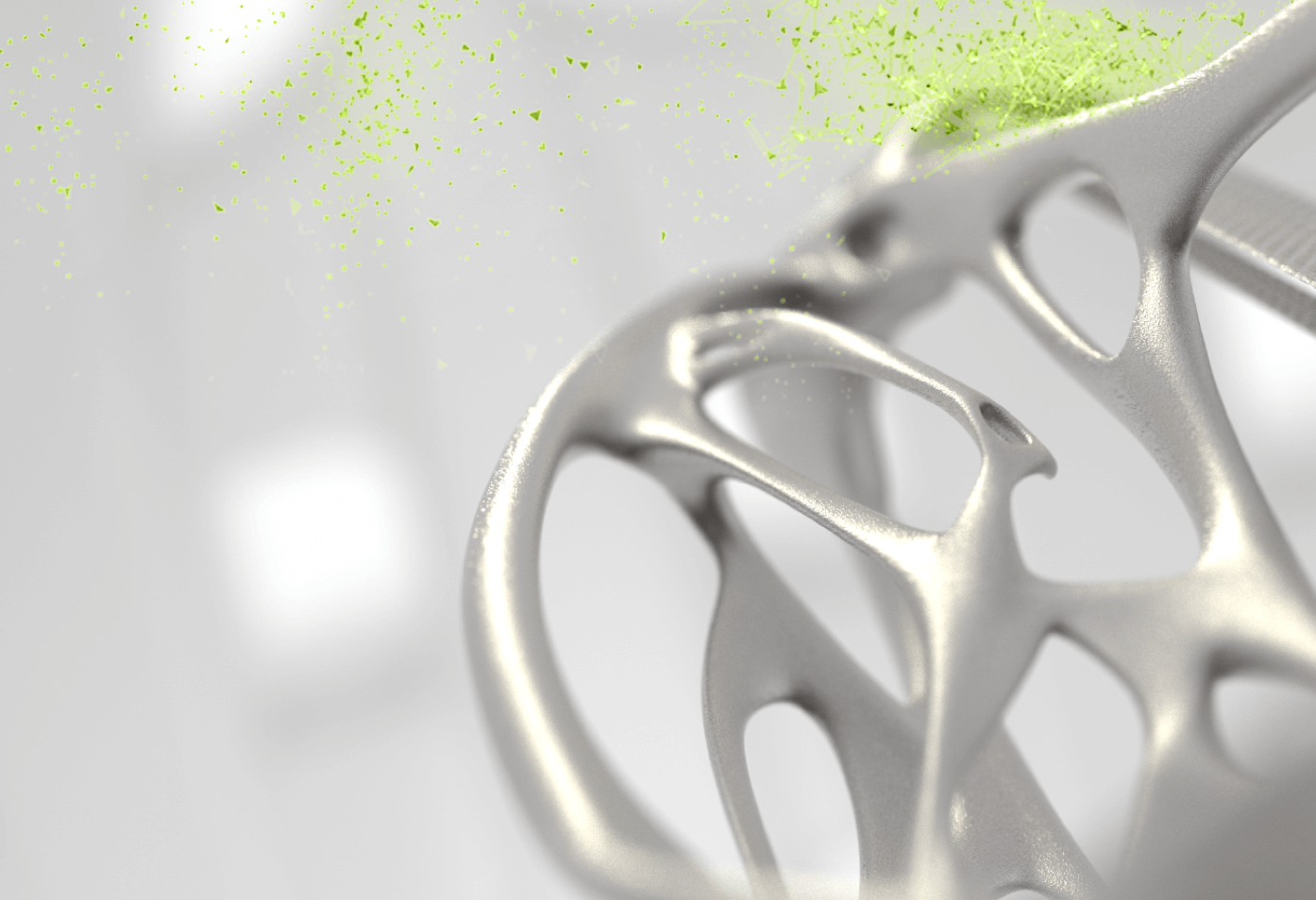

The secret to SLM Solutions' success in supporting so many industries is our open architecture platform. Open architecture puts you in control to customize SLM® machines to fit your metal AM application.

Powder Variability - You are free to choose your powder in all machines. SLM Solutions carries a variety of metal alloy powder but our machines also allow you to use powder from your favorite supplier for maximum flexibility.

Open Process Parameters - Like any metal AM machine, SLM® machines come ready to print with standard parameter sets right out of the box. However, open architecture means you have access to open process parameters with full control of the parameters in the build processor and the material development module.

Variable Control - There is a total system variable control at all levels to suit your requirements.

LEARN MOREWe empower our customers, our teams and our industry with leading technology and the most advanced materials. We give our teams the necessary tools to create cutting edge technology, we give our clients the cutting edge technology to create their dreams, and we give our industry the dreams to shape the future.